Recycle & remanufacture

Along with UD Truck’s efforts to reduce waste and increase recycling in its production activities, there is an increasing awareness of the need to recycle every possible part of the vehicle, and to remanufacture parts removed from vehicles. When a truck nears the end of its useful life, many of its components still have value. Today, every possible part and material is remanufactured or recycled, so that only a tiny fraction of the total has to be permanently disposed of in landfills. Based on the requirements of Japan’s Automobile Recycling Law of 2005, UD Trucks recycles the automotive shredder dust, airbags and fluorocarbons recovered from end-of-life vehicles (ELVs). A waste management system instituted at UD Trucks dealers separates waste into 26 categories, while an increasing number of parts retrieved from exchanges made during maintenance are remanufactured as genuine parts.

a442.jpg?la=en-int)

Recycling

The Automobile Recycling Law, which came into effect in 2005 in Japan, requires manufacturers to collect, recycle and appropriately handle three classes of materials resulting from the treatment of end-of-life vehicles (ELVs): automotive shredder residue (ASR), airbags, and fluorocarbons. The manufacturers must also report each year on their achievements in the recovery of resources from ELVs.UD Trucks has implemented an efficient vehicle recycling system to appropriately handle materials in all three categories. The process of resource recycling is now a highly transparent, efficient system, with the Automobile Shredder Residue Recycling Promotion Team (ART) handling ASR, while airbags and fluorocarbons are processed by the Japan Automotive Recycling Promotion Center (JARC).

For the year beginning in April 2012, the process handled 1,261.6 tons of ASR from 3,350 trucks, 1,029 airbags from 596 vehicles, and 1,129 kilograms of fluorocarbons from 2,789 trucks.

UD Trucks will continue to act in accordance with the goals of the Automobile Recycling Law, continuing to develop its system for the efficient recycling of ELVs and helping to build a true recycling-oriented society.

Clean dealerships

Apart from the final disposal of the vehicle, nowhere else are more waste materials generated than at UD Trucks’ nationwide network of dealers and workshops. Regular servicing means that drums, old mufflers and other parts, sludge, used oils and fluids, old tires and a range of others parts and substances must be properly handled on a dally basis.To respond to this, UD Trucks has recently developed a new waste management system and implemented it at its dealers in Japan. This nationwide program for the correct handling, treatment and disposal of these materials will also help reduce environmental impact. Waste is separated into 26 categories and collected in specialized storage facilities, waste bins, containers and so on. Each item is then recycled, rendered harmless as much as possible, or processed using the best available methods.

Since 2013, 24 specialized waste separation facilities and 32 other facilities have opened as part of this system. Plans also call for the construction of an additional 45 specialized facilities. At UD Trucks, the appropriate management of waste, the effective utilization of resources and the reduction of environmental impact are all part of the continuous development of its waste management system.

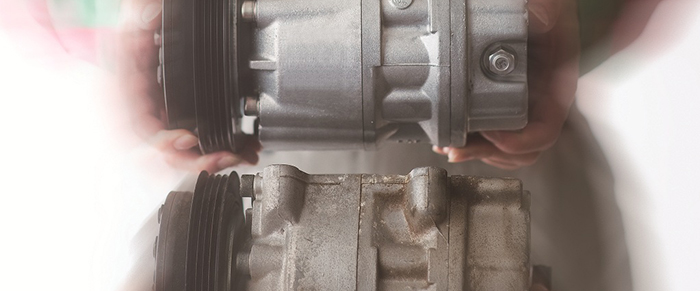

New life for old parts

UD Trucks is proud of its reputation for building tough trucks. That includes the robust parts that make up the vehicle—which can have a second career as refurbished units. These provide the same quality as other UD Genuine Parts, but at an even more affordable price.Remanufacturing parts from those removed during servicing makes sense in several ways. Remanufactured parts are produced from cores; the parts have been removed from the vehicles on which they were originally used. These cores are collected, inspected, disassembled, cleaned, given replacements for any deteriorated components, assembled and tested according to the latest specification. These parts are made useful again—an excellent way to reuse resources.

UD Trucks also ensures that the parts have exactly the same quality, and provide the same performance, as brand new products. Customers also benefit from lower cost and the reliability of using UD exchange parts. Replacement using these parts assemblies reduces the time and labor involved in overhauls, which means reduced downtime for the truck.

UD Trucks offers a wide range of exchange parts to original standards, including brake-related parts such as brake valves and air dryers, clutch-related parts, engine parts such as starter motors and generators, transmission parts including power shifts and gearshift units, and even remanufactured engines, transmissions and differentials. Today, approximately 10% of the UD Genuine Parts sold in Japan are exchanged parts.