Innovation that puts people first.

Smart quality through thorough extra mile testing

As a UD truck, All New Quon embodies the idea of Ultimate Dependability. The concept permeates the entire cycle, from the design of the truck to the final manufacturing. To ensure the reliability of All New Quon, the truck has been submitted to extreme tests.UD's quality assurance program includes tests of safety, performance, reliability and durability. It took a total of 2.5 million engineering hours to develop All New Quon; 92 vehicles were deployed for test-drive for a total of over 6 million kilometers; 15,858 hours were spent on bench test to simulate the worst conditions, to check 82 points of control.

Every detail was thoroughly checked through sophisticated processes under the supervision of an international team of highly trained engineers, leading to further improvements and optimizations, to reach the quality and durability every UD truck owner should expect. Below are some examples of how UD went the extra mile in testing All New Quon.

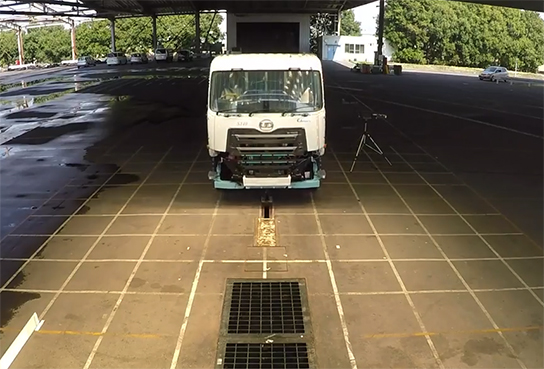

Durability bench tests

Cabin and chassis durability was tested using accurate simulations of very tough road surfaces.

Cold tests

Long-term tests were conducted in the northern Japanese island of Hokkaido and in northern Sweden. Japanese and European engineers in extremely cold temperatures lengthily tested reliability, drivability and safety.

Cold start and clean exhaust emissions

Slippery road starts

Braking tests on icy surfaces

Performance tests on snow- and ice-covered roads

Collision tests

Collision tests simulate all kinds of accidents to ensure that both driver and passenger are protected.

Visit All New Quon launch site!

Watch All New Quon videos on YouTube!